Key Features

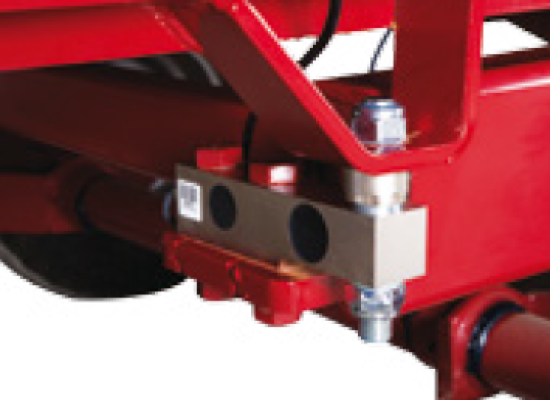

- Tandem axle with 3 positions for variable draw-bar loading

- Manual feed rate control

- Ladder, mudguards/walkways and LED tail lights fitted

- Double chassis ready for scales

- High tensile floor shaft

- Priority belt speed control

- Stainless steel sides for corrosion and wear resistance

- Mesh front screen and back gate for good visibility

- Self-releasing back gate - opens automatically when bulk unloading

- Central greasing system for difficult-to-access bearings and remote greasing on tandem axle bushes and elevator

- Cast iron bearings for long life

- 35mm treated T&G pine floor for extra durability

Giltrap RF9 Specifications

- RF9

- 6.075

- 2.530

- 2.610

- 2.200

- 3.800

- 1.230

- 2.050

- 2470

- 9.0

- 900

- 2

- 4 x 5000

- 80 screw

- Tandem

- 60 (6 stud)

- 11.5/80 x 15.3